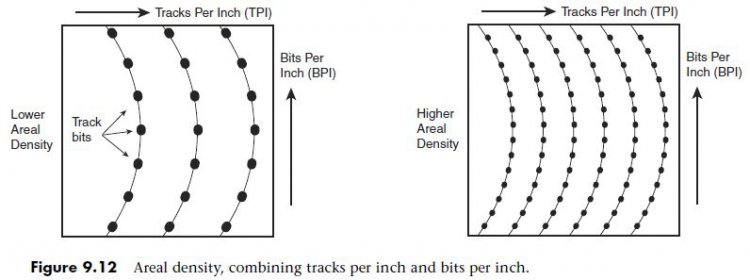

Areal Density

Areal density is often used as a technology growth-rate indicator for the hard disk drive industry. Areal density is defined as the product of the linear bits per inch (BPI), measured along the length of the tracks around the disk, multiplied by the number of tracks per inch (TPI), measured radially on the disk (see Figure 9.12). The results are expressed in units of megabits or gigabits per square inch (Mbit/sq. inch or Gbit/sq. inch) and are used as a measure of efficiency in drive recording technology. Current high-end 3 1/2" drives record at areal densities exceeding 60Gbit/sq. inch (such as the 400GB Hitachi 7K400, which records at 61.7Gbit/sq. inch), whereas 2 1/2" drives such as the 80GB Hitachi 5K80 record at areal densities of 70Gbit/sq. inch or more. Prototype drives with densities of 130Gbit/sq. inch or more now exist, which will enable 3 1/2" drives with capacities of 1 terabyte (TB) or more in the next few years.

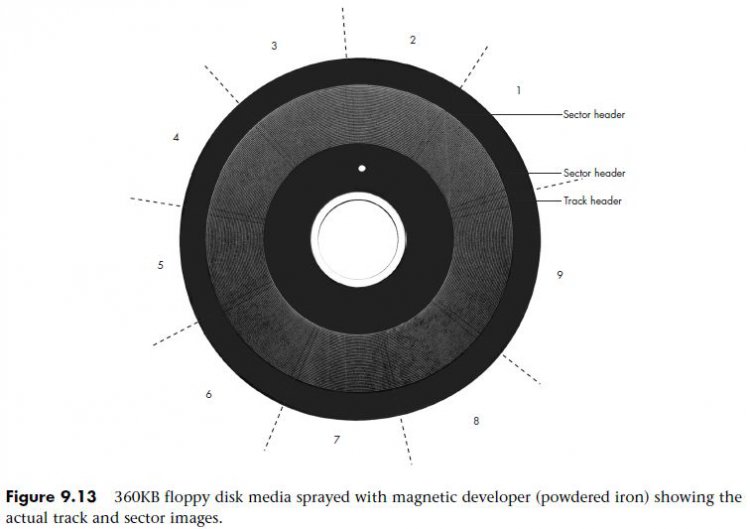

Drives record data in tracks, which are circular bands of data on the disk. Each track is divided into sectors. Figure 9.13 shows an actual floppy disk sprayed with magnetic developer (powdered iron) such that an image of the actual tracks and sectors can be clearly seen. The disk shown is a 5 1/4" 360KB floppy, which has 40 tracks per side, with each track divided into 9 sectors. Note that each sector is delineated by gaps in the recording, which precede and postcede the track and sector headers (where ID and address information resides). You can clearly see the triple gap preceding the first sector, which includes the track and sector headers. Then following in a counterclockwise direction, you see each subsequent sector, preceded by gaps delineating the header for that sector. The area between the headers is where the sector data is written.

Notice that sector 9 is longer than the others; this is to enable rotational speed differences between drives, so that all the data can be written before running into the start of the track. Also notice that a good portion of the disk surface isn’t used because it is simply impractical to have the heads travel in and out that far, and the difference in length between the sectors on the inner and outer tracks becomes more of a problem.

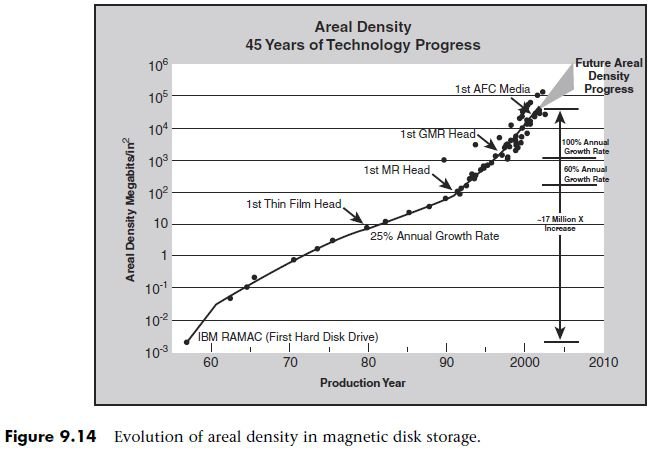

Areal density has been rising steadily since the first magnetic storage drive (IBM RAMAC) was introduced in 1956, initially at a growth rate of about 25% per year (doubling every four years), and since the early 1990s at a growth rate of about 60% per year (doubling every year and a half). The development and introduction of magneto-resistive heads in 1991, giant magneto-resistive heads in 1997, and AFC pixie dust media in 2001 have propelled the increase in the areal density growth rate. In the 47+ years since the RAMAC drive was introduced, the areal density of magnetic storage has increased more than 17 million fold.

At the current growth rate, within the next three years or so, drive manufacturers will achieve areal densities of approximately 100Gbit/sq. inch, which is considered near the point at which the superparamagnetic effect takes place. This is an effect in which the magnetic domains become so small that they are intrinsically unstable at room temperature. Techniques such as extremely high coercivity media and vertical polarity recording are projected to enable magnetic storage densities of 400Gbit/sq. inch or more, but beyond that, scientists and engineers will have to look toward other technologies. One such technology being considered for the future is holographic storage, in which a laser writes data three-dimensionally in a crystal plate or cube.

To increase areal density while maintaining the same external drive form factors, drive manufacturers have developed media and head technologies to support these higher areal densities, such as ceramic/glass platters, GMR heads, pseudo-contact recording, and PRML electronics, as discussed earlier in this chapter. The primary challenge in achieving higher densities is manufacturing drive heads and disks to operate at closer tolerances. Improvements in tolerances and the use of more platters in a given form factor continue to fuel improvements in drive capacity, but drive makers continue to seek even greater capacity increases, both by improving current technologies and by developing new ones.

To fit more data on a platter of a given size, the tracks must be placed more closely together and the heads must be capable of achieving greater precision in their placements over the tracks. This also means that as hard disk capacities increase, heads must float ever closer to the disk surface during operation. The gap between the head and disk is as close as 10 nanometers (0.01 microns) in some drives, which is approximately the thickness of a cell membrane. By comparison, a human hair is typically 80 microns in diameter, which is 8,000 times thicker than the gap between the head and disk in some drives. The prospect of actual contact or near contact recording is being considered for future drives to further increase density.

Increasing Areal Density with Pixie Dust

In 1990, IBM scientists discovered that a thin layer of the element ruthenium was the most effective nonmagnetic element that could be used for spacers in devices such as GMR heads. However, more than a decade passed before the first commercially available application of this principle was used to increase disk drive storage densities by improving the storage density of the drives’ platters.

In May 2001, IBM began to produce drives using “pixie dust” technology in its Travelstar 2 1/2" hard drive series for notebook computers. In November 2001, Deskstar GXP drives using the same technology were introduced, and these drives had capacities of 80GB and 120GB.

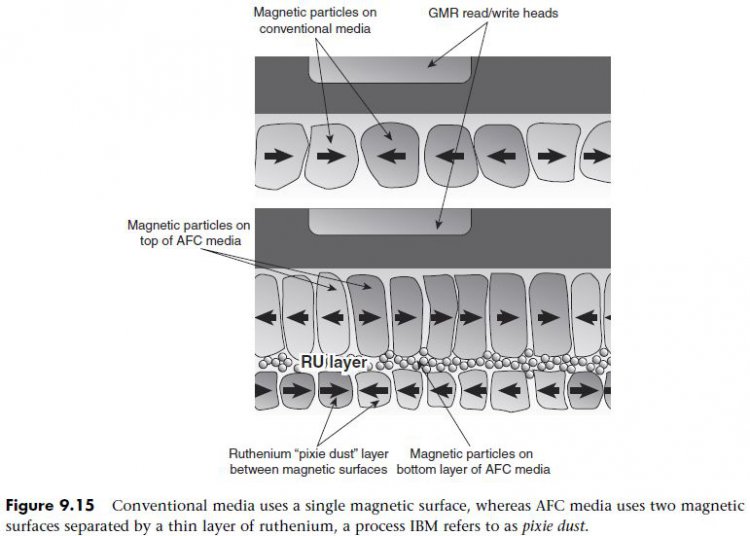

These drives achieved data densities exceeding 25Gb per square inch through the use of a thin (three-atom-thick) layer of ruthenium used to separate two magnetic surfaces on each side of the drive’s platters. Traditional drives use platters with a single magnetic surface per side. Media using the ruthenium coating, commonly referred to as pixie dust, is technically known as antiferromagnetically coupled

(AFC) media. IBM continues to use AFC media in its latest drives for notebook, desktop, and server computers and has licensed AFC media to other drive and media vendors.

AFC media was developed because achieving greater and greater densities of magnetic storage requires individual magnetic areas on the media to become smaller and smaller. However, when magnetic areas become too small, a problem called the superparamagnetic effect (which causes magnetic areas to lose their magnetism over time) can occur.

When a thin layer of ruthenium is placed between two magnetic layers, the layers are forced to orient themselves magnetically in opposite directions to each other. Although the three-layer structure is physically thicker than a conventional magnetic surface, the opposing magnetic orientations make the layers appear to be thinner than a conventional surface. As a result, disk drive read/write heads can record smaller, high-density signals, increasing the storage capacity of a given platter size without the risk of the signal degrading. Figure 9.15 compares a normal single-layer disk platter to a disk platter using pixie dust AFC media technology.

Just as GMR heads use two layers separated by a thin conductive layer to increase data storage density, AFC media uses a similar principle. In essence, AFC media represents an extension of GMR principles from the read/write heads to the media’s data recording surfaces. Over time, AFC media is expected to quadruple the storage capacity of magnetic media, enabling drives to reach capacities of 100Gb per square inch or more. In practical terms, such capacity could result in desktop 3 1/2'' hard drives of up to 1TB, 2 1/2'' notebook hard drives of up to 300GB, and IBM Microdrives (which have a 1'' wide platter) of 8GB or more.

)

)